Digital Twins

Our team specializes in enhancing operations with Digital Twin technology, offering advanced solutions for real-time monitoring, predictive maintenance, and asset optimization. By creating virtual replicas of your building, we enable data-driven decisions, improve efficiency, and extend the lifespan of your assets, all while minimizing downtime.

Digital Twins

Imagine a dynamic, interactive model that contains every detail of your assets, offering real-time insights and empowering you to manage operations from anywhere. It’s not just convenient—it’s a game changer. Let’s take a closer look at how this transformative technology works.

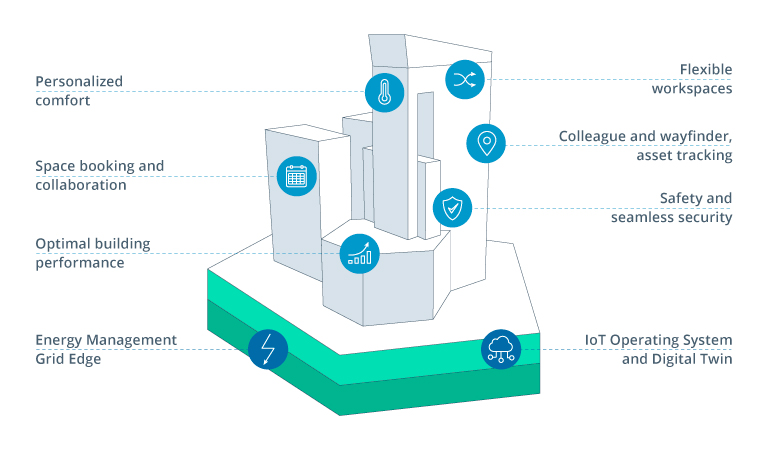

Digital Twins are virtual replicas of physical assets, systems, or processes that allow for real-time monitoring, analysis, and optimization. By integrating real-world data with advanced modeling, Digital Twins provide deep insights into performance, maintenance needs, and operational efficiencies. This technology enables proactive management, enhances decision-making, and helps optimize resource usage, making it invaluable in industries like construction, manufacturing, and facility management. With the ability to simulate, predict, and control, Digital Twins help improve overall asset performance and longevity.

Why Choose Tecverse

Tecverse stands out as a top provider of BIM solutions, offering a blend of innovation, strong industry partnerships, and a customer-centric approach that ensures the highest level of quality and efficiency in every project.

FAQs

A Digital Twin is a virtual replica of a physical object, process, or system. It integrates real-time data from sensors, providing a real-time simulation that reflects the current state of the asset. Digital Twins are used for monitoring, analysis, and optimization of operations.

Digital Twins improve asset management by offering continuous monitoring of assets through real-time data. This enables better tracking of asset conditions, predicting potential failures, and optimizing maintenance schedules, leading to reduced downtime and increased asset life.

Digital Twins contribute to sustainability by enabling efficient resource management, reducing waste, and improving energy consumption. They help identify inefficiencies, streamline operations, and reduce the environmental impact of buildings and infrastructure over their lifecycle.

Industries like construction, healthcare, manufacturing, transportation, and urban planning benefit from Digital Twins. These virtual models allow for better decision-making, enhanced operational efficiency, and predictive maintenance across a wide range of assets.

Digital Twins enhance decision-making by providing real-time, accurate data and simulations. By visualizing data trends, performance metrics, and possible scenarios, decision-makers can optimize operational strategies, improve productivity, and respond proactively to emerging issues.

Yes, Digital Twins can be integrated with IoT devices. By collecting data from IoT sensors, these digital replicas are continuously updated, providing accurate insights into real-time performance, environmental conditions, and asset health, allowing for predictive maintenance and smart optimization.

Challenges in implementing Digital Twins include the high cost of initial setup, data integration complexity, and the need for advanced technology infrastructure. Additionally, maintaining the accuracy of the digital twin over time and ensuring interoperability with other systems can be challenging.

.webp)

Innovate, Build, Deliver

Get in touch with us to discover how we can empower your team to harness cutting-edge construction technologies for quicker and more impactful outcomes.